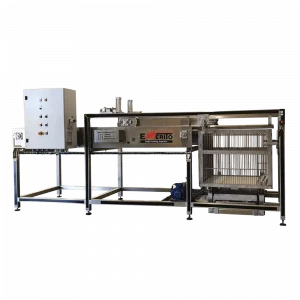

Rinsing Machines

For empty containers

This rinsing machine is designed specifically to carry out the cleaning of empty containers used in food production processes, even if they are made in plastic, tin or glass.

The containers washing machine, which is built mainly in first quality AISI 316L steel, automates the washing of containers without the need of adding additional tools, thus achieving a significant improvement in production capacity as well as an efficiency in the use of personnel, which means an immediate improvement of competitiveness.

The nature of the materials used in its manufacture, together with the unquestionable quality in manufacturing finishes, makes this machine an instrument for reliable and long lasting to help extend life even in situations of more demanding and committed work.

In addition, thanks to the modern concept of manufacturing that the machine has, the need for maintenance, which has been simplified to the maximum is reduced until the end. This ensures us always the best results in the short and long term.

It is also important to highlight the modularity of the equipment, since we can always adapt it to the needs of the client, either using a sanitizing system only, or by combining several of them (up to three): blowing, both rinsing and/or steaming to always achieve the best results.

Container washing automation

Our Models

- U1

- U2

- U2 - SP

- Universal

Containers

Jars, cans, PET, bottles, etc. All format and sizes.

Capacity

Up to 40 containers / min.

Versatility

Need of a formats shapes confirmation.

Containers

Jars, cans, PET, bottles, etc. All format and sizes.

Capacity

Up to 150 containers / min.

Versatility

All containers without

installation of additional elements.

Easy format change

adjustment by opening lateral belts.

Containers

Jars, cans, PET, bottles, etc. All format and sizes.

Capacity

Up to 200 containers / min.

Versatility

Easy adjustment for the change of different formats.

Containers

Jars, cans, PET, bottles, etc. All format and sizes.

Capacity

Up to 600 containers / min.

Versatility

All containers without installation of additional elements.

Easy adjustment for the change of different different formats.

Take a look at our catalogue

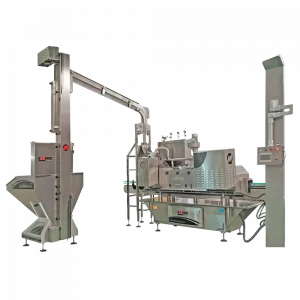

Equipment designed to depalletize rigid empty containers such as

that are already palletized, with the function to align them one by one and lead them correctly to the packaging line. It can also be used at the end of the line with full containers to align them one by one and lead them to the batch marking and labeling area.

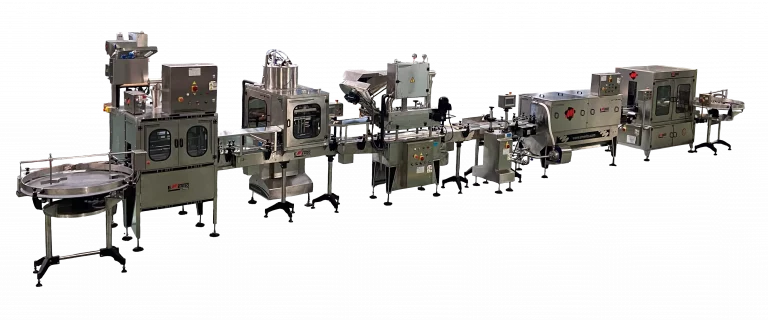

Twist Off and PT closures. Totally adapted to your needs. Total versatility in containers, lids and products. In addition, we have the fastest container format changeover in the market.

Low Productions (Up to 40 cpm)

Emerito S1 Emerito 0.8 Emerito 4.8

Medium Productions (Up to 70 cpm)

Emerito 1.8 Emerito 1.8G

Medium-High Productions (Up to 200 cpm)

Emerito 2.8 Emerito 2.8 M2

High Productions (Up to 600 cpm)

Emerito 3.8 Emerito 5.8

Equipment that controls the quality of food packaging, checking the vacuum of each food and the placement of the lid.

Equipment designed to avoid the overfilling of solid product in the containers, prior to being closed.

Machines designed to insert and extract already closed containers into the baskets normally used in horizontal autoclaves. They can be automatic or semi-automatic, depending on the needs of each packaging line.

We have equipment to complement the processes, such as accumulation and feeding plates and tables, conveyor belts and electric steam generators.