Emerito S1 Semiautomatic Capper

-

Types Of Closure

Twist-Off & PT

-

Lids

Diameter: From TO38 to TO110

Height: From 9 to 18 mm -

Containers

Diameter: From 30mm to 160 mm

Height: From 40mm to 260mm -

Container Format Changeover

By means of mechanical adjustments

Designed and intended for artisan producers and laboratories.

Semi-automatic machine designed and intended for artisan producers and laboratories. Twist Off lid closing system equipped with a magnetic head where the operator places the lid and then actuates the buttons located on both sides of the machine, thus allowing the closing head to operate with all the safety guarantees.

The closing head acts by means of an air-operated clutch whose pressure can be adjusted between 0.5 and 4 Nm according to the required need in each case.

This semi-automatic equipment is equipped with a handwheel with counter that facilitates the adjustment of the height of each container to be closed. It also has a system for anchoring the container by means of a pneumatic cylinder and a mechanical stopper to prevent the container from turning during the closing operation, thus ensuring that the process has been carried out correctly. This clamping system allows the use of cylindrical and square containers, as well as hexagonal or octagonal ones.

Technical Specifications

Semi-automatic machine designed and intended for artisan producers and laboratories. Twist Off lid closing system equipped with a magnetic head where the operator places the lid and then actuates the buttons located on both sides of the machine, thus allowing the closing head to operate with all the safety guarantees.

The closing head acts by means of an air-operated clutch whose pressure can be adjusted between 0.5 and 4 Nm according to the required need in each case.

This semi-automatic equipment is equipped with a handwheel with counter that facilitates the adjustment of the height of each container to be closed. It also has a system for anchoring the container by means of a pneumatic cylinder and a mechanical stopper to prevent the container from turning during the closing operation, thus ensuring that the process has been carried out correctly. This clamping system allows the use of cylindrical and square containers, as well as hexagonal or octagonal ones.

Technical Features

Take a look at all our capping machines

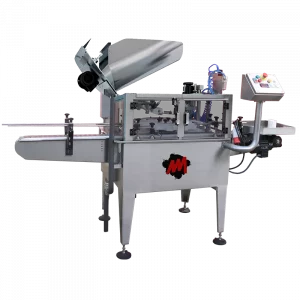

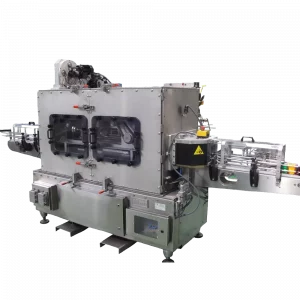

Semi-automatic capping machine for glass or PET containers with a capacity of up to 500 or 600 units per hour.

- Up to 40 cpm

- Semiautomatic

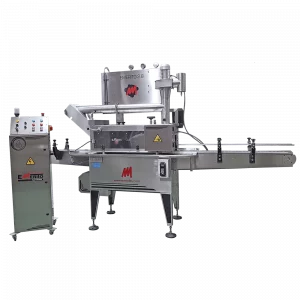

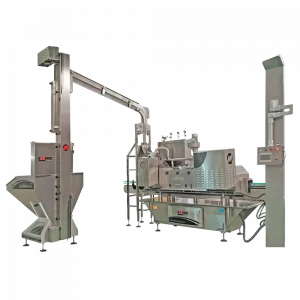

Capping machine for glass or PET containers designed for small producers with a capacity of up to 20 units per minute.

- Up to 20 cpm

- Automatic

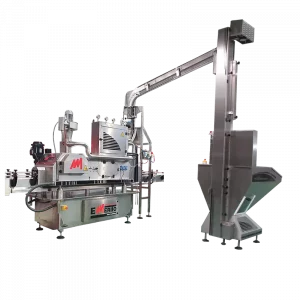

- Up to 70 cpm

- Automatic

- Up to 70 cpm

- Automatic

- + Versatility

Capping machine for glass or PET containers with a capacity of up to 130 units per minute.

- Up to 130 cpm

- Motorised Format Chageover

Capping machine for glass or PET containers with a capacity of up to 200 units per minute.

- Up to 200 cpm

- Automatic Format Changeover

Machine à fermer les pots en verre ou en PET avec une capacité jusqu’à 300-330 unités par minute.

- Up to 330 cpm

- Changement automatique de format

Capping machine for glass or PET bottles with products that need no humid atmosphere with a capacity of up to 40 units per minute.

- Up to 40 cpm

- Bottles Without Humid Atmosphere

- Up to 600 cpm

- Automatic Format Changeover