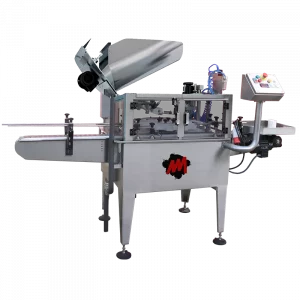

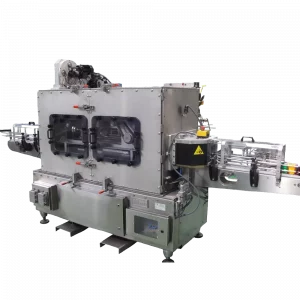

Emerito 2.8 M2 Capper

-

Types Of Closure

Twist-Off & PT

-

Lids

Diameter: From TO27 to TO110

Height: Up to 18 mm (DTO) -

Containers

Diameter: From 30 mm to 160 mm (gallon)

Height: From 40 mm to 260 mm

Intermediate production equipment.

Bottle closing machine for glass, pet, etc. formats, for TWIST-OFF and PT type closing system. Also PET bottles with Twist Off lids depending on the quality and rigidity of the bottle.

It is fully equipped to close all formats of containers and lids commonly used in food processing (jars, jars, bottles, etc.), without the need to incorporate additional tools or complements.

It incorporates an exclusive, fully automatic, intelligent format changeover as standard, which regulates with total precision; container height, width, relative position of the side belts depending on the height and shape of the format to be closed.

Changeover time between containers of maximum difference: 70 seconds.

An alternative version, the Emerito 2.8 M2 ACT, is available for containers impregnated with oils or greasy substances and, thanks to its special configuration, guarantees 100% closure even in these extreme conditions.

Standard Version

200 units per minute | 12.000 units per hour

ACT Version

170 units per minute | 10.200 units per hour

There is also a version of the Emerito 2.8 M2 capper that does not incorporate automatic format changeover with a closing capacity of 12,000 units/hour in the belt version and 10,200 units/hour in the ACT version.

Options

- Connection to rotary plate

- Lateral traction

- Steam management system

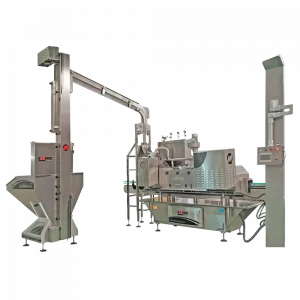

For feeding the containers to the packaging lines, as well as for accumulating.

For container transport, with double belt.

For preheating the lids and for injecting steam into the equipment, which facilitates the creation of the safety vacuum.

Standard Components

• Automatic lid feeder by magnetic column.

• Lid positioner by mechanical selector.

• Lid presence‐absence detector in the feeder.

• Easy system for caps removal in hopper.

• Minimum level signal of caps in hopper.

• Universal caps drop, valid for all caps sizes.

• Exclusive “pre‐lid screw‐on control” system in the preclosing assembly.

• Fitting for steam inlet to pre‐heat the lids and facilitate the safety vacuum.

• Liquid recovery tray (cooling water, overflows, etc.).

• High‐end motorised headstock for changing format height.

• Dynamic elements synchronized with inverters.

• Independent and centralised controller.

• Lateral belts regulation from central steering wheel.

• Adjustable height from control panel.

• Side pressure bands for container transport.

An alternative version, the Emerito 2.8 M2 ACT, is available for containers impregnated with oils or greasy substances and, thanks to its special configuration, guarantees 100% closure even in these extreme conditions.

Standard Version

200 units per minute | 12.000 units per hour

ACT Version

170 units per minute | 10.200 units per hour

Standard Components

• Automatic lid feeder by magnetic column.

• Lid positioner by mechanical selector.

• Lid presence‐absence detector in the feeder.

• Easy system for caps removal in hopper.

• Minimum level signal of caps in hopper.

• Universal caps drop, valid for all caps sizes.

• Exclusive “pre‐lid screw‐on control” system in the presclosing assembly.

• Fitting for steam inlet to pre‐heat the lids and facilitate the safety vacuum.

• Liquid recovery tray (cooling water, overflows, etc.).

• High‐end motorised headstock for changing format height.

• Dynamic elements synchronized with inverters.

• Independent and centralised controller.

• Lateral belts regulation from central steering wheel.

• Adjustable height from control panel.

• Side pressure bands for container transport.

Options

Lateral traction for container transport, with double belt.

Connection to supply and/or storage plate

Steam management system for preheating the lids and injecting steam into the equipment, which facilitates the creation of the safety vacuum.

Lateral traction for container transport, with double belt.

Take a look at all our capping machines

Semi-automatic capping machine for glass or PET containers with a capacity of up to 500 or 600 units per hour.

- Up to 40 cpm

- Semiautomatic

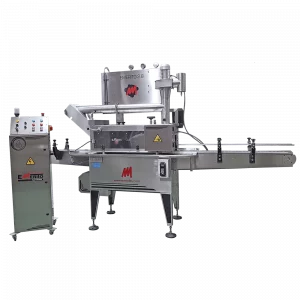

Capping machine for glass or PET containers designed for small producers with a capacity of up to 20 units per minute.

- Up to 20 cpm

- Automatic

- Up to 70 cpm

- Automatic

- Up to 70 cpm

- Automatic

- + Versatility

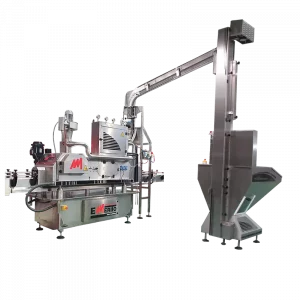

Capping machine for glass or PET containers with a capacity of up to 130 units per minute.

- Up to 130 cpm

- Motorised Format Chageover

Capping machine for glass or PET containers with a capacity of up to 200 units per minute.

- Up to 200 cpm

- Automatic Format Changeover

Machine à fermer les pots en verre ou en PET avec une capacité jusqu’à 300-330 unités par minute.

- Up to 330 cpm

- Changement automatique de format

Capping machine for glass or PET bottles with products that need no humid atmosphere with a capacity of up to 40 units per minute.

- Up to 40 cpm

- Bottles Without Humid Atmosphere

- Up to 600 cpm

- Automatic Format Changeover