Vacuum Leak Detector

The vacuum leak detector is a fundamental equipment in terms of food safety. It is designed for quality control in food packaging lines and works by checking the existence of vacuum inside the containers, as well as the correct positioning of the lid and the presence or absence of the same. In addition to ejecting from the line the containers without vacuum, it avoids the continuation of the process those containers that are not properly closed or without a lid, thus ensuring that they do not generate problems in the subsequent heat treatment part.

Placed in the part before labeling, we will avoid that any container without safety vacuum can be stored or taken to the market.

The expulsion of the incorrect containers is done to a reject tray or in case of high speeds to a conveyor or dynamic table in parallel, which Emerito S.L. offers as a complement if necessary. We also offer as an option a hinged belt where the equipment can be placed if the customer requires it or in case of not having a sufficiently stable belt for the correct reading of the parameters.

The software that incorporates our vacuum detector (developed completely by EMERITO), allows you to generate different types of notices or both audible and visual alarms and schedule them conveniently to have controlled the range of failures all the time.

It can be installed in two crucial points of production: out of the capper, avoiding that wrong closed containers come into the phase of heat treatment; or on possible further steps, preventing containers showing some kind of anomaly back to sterilization or the heat treatment stage, to pass to the phase of labeling and storage generating further problems of quality and presentation to the market.

It also allows control of tin containers, rejecting those which present dents or deformities.

Take a look at our catalogue

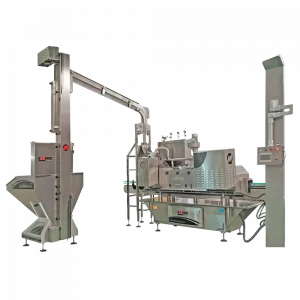

Equipment designed to depalletize rigid empty containers such as

that are already palletized, with the function to align them one by one and lead them correctly to the packaging line. It can also be used at the end of the line with full containers to align them one by one and lead them to the batch marking and labeling area.

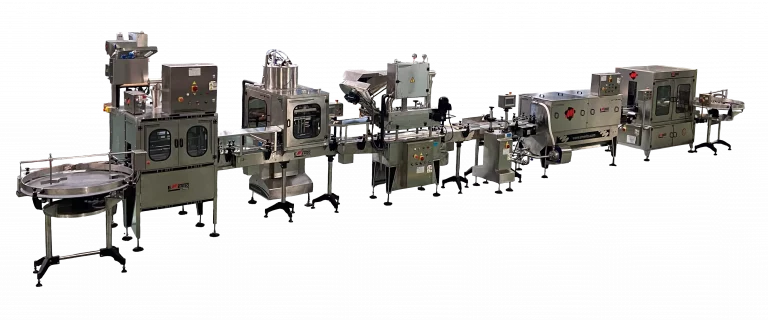

Twist Off and PT closures. Totally adapted to your needs. Total versatility in containers, lids and products. In addition, we have the fastest container format changeover in the market.

Low Productions (Up to 40 cpm)

Emerito S1 Emerito 0.8 Emerito 4.8

Medium Productions (Up to 70 cpm)

Emerito 1.8 Emerito 1.8G

Medium-High Productions (Up to 200 cpm)

Emerito 2.8 Emerito 2.8 M2

High Productions (Up to 600 cpm)

Emerito 3.8 Emerito 5.8

Equipment that controls the quality of food packaging, checking the vacuum of each food and the placement of the lid.

Equipment designed to avoid the overfilling of solid product in the containers, prior to being closed.

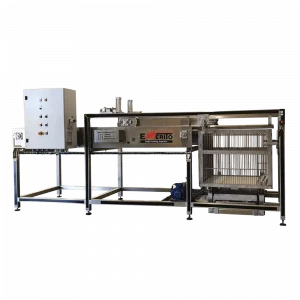

Machines designed to insert and extract already closed containers into the baskets normally used in horizontal autoclaves. They can be automatic or semi-automatic, depending on the needs of each packaging line.

We have equipment to complement the processes, such as accumulation and feeding plates and tables, conveyor belts and electric steam generators.