Used Machinery

In this section you will find commercial opportunities to acquire fully reconditioned Emerito machinery.

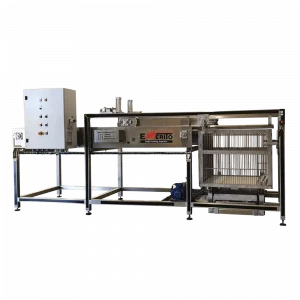

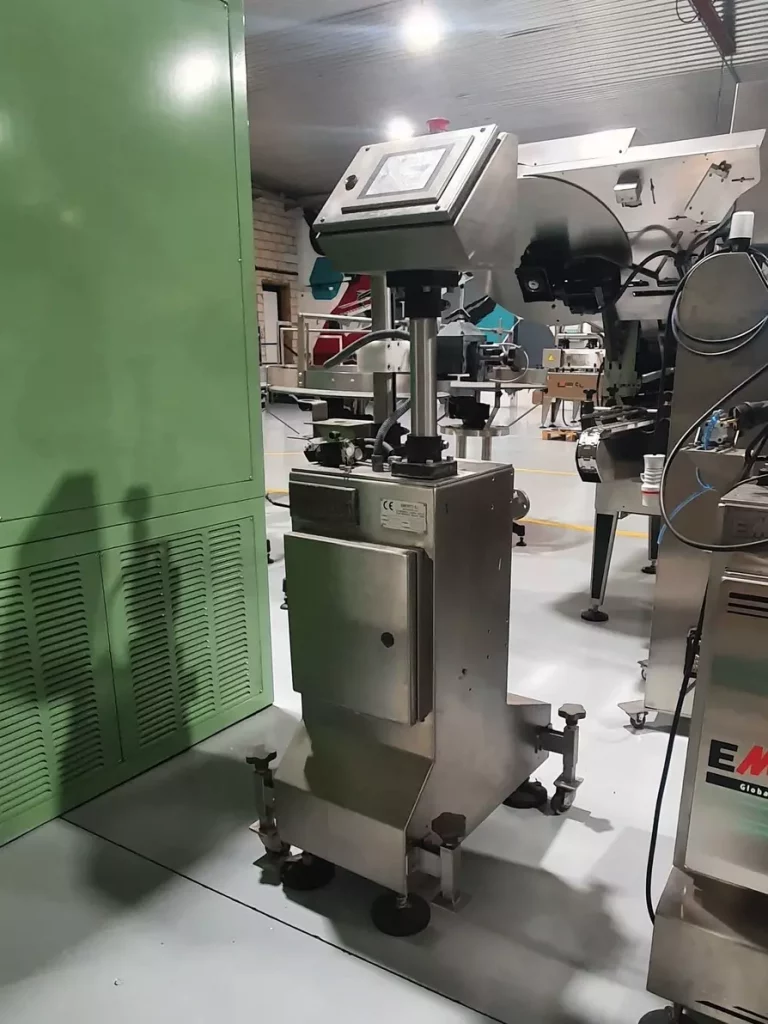

Emerito 2.8 Capping Machine (Ref. E229R-TCT)

Emerito 2.8 glass jar capper

Equipment completely reconditioned in Emerito, S.L. The maximum production rate of this equipment is 130 containers per minute. Includes steam pre-installation system.

Includes steam extraction.

Estimated delivery time: inmediately

The equipment is delivered completely updated. Date: 2006

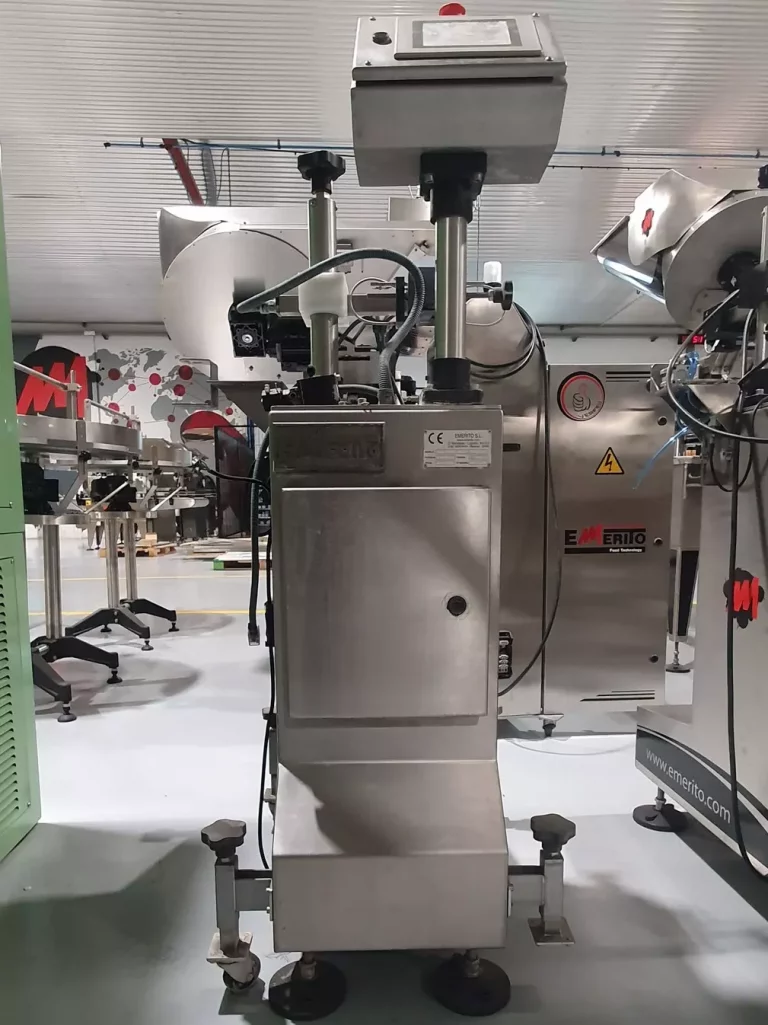

Emerito 2.8 Capping Machine (Ref. VT)

Emerito 2.8 glass jar capper

Equipment completely reconditioned in Emerito, S.L. The maximum production rate of this equipment is 130 containers per minute. Includes steam pre-installation system.

Includes steam extraction.

Estimated delivery time: inmediately

The equipment is delivered completely updated. Date: 2006

(AVAILABLE) Emerito DVI 400 (Ref. D1720FA)

Equipment designed for safety vacuum control in food packaging lines in glass jars.

It is also indicated for the rejection of jars without lid or with the lid incorrectly placed.

Valid also for rejecting from the line those cans that may be defective, deformed or dented.

<

In the case of cans with easy-openers, the reading of the cans has to be done on the opposite side. Year of manufacture: 2017

(AVAILABLE) Emerito DVI 400 (Ref. D0227DB)

Equipment designed for safety vacuum control in food packaging lines in glass jars.

It is also indicated for the rejection of jars without lid or with the lid incorrectly placed.

Valid also for rejecting from the line those cans that may be defective, deformed or dented.

<

In the case of cans with easy-openers, the reading of the cans has to be done on the opposite side. Year of manufacture: 2017

Emerito 1.8 ACT Capping Machine (Ref. P172SD) (SOLD)

Emerito 1.8 ACT Automatic Capping Machine. Equipment completely reconditioned in Emerito, S.L. The maximum production rate of this equipment is 50 containers per minute. It includes steam pre-installation system. The equipment is delivered completely updated. Year of manufacture: 2017

Emerito 1.8 ACT Capping Machine (Ref. C0420FCV) (SOLD)

Glass jar capper, model Emerito 1.8 ACT. Semi-new equipment. It incorporates the special system for the closing of containers that are impregnated with oil (ACT) ensuring 100% quality of the closure. The maximum production rate of this equipment is 50 containers per minute. Includes steam management system. Estimated delivery time from the confirmation of the equipment 4 weeks. Year of manufacture: 2017

Emerito 1.8 ACT Capping Machine (Ref. C9820PLS) (SOLD)

TWIST-OFF and PT type automatic jar capper, totally upgraded by Emerito.

Permite cerrar un amplio rango de formatos; como botellas, tarros, frascos, etc. sin necesidad de incorporar complementos adicionales.

Este modelo incluye de serie motorización de ajuste de diferentes alturas de envases.

Emerito 2C 4C Volumetric Sauces & Liquids Filler (Ref. D1920NT) (SOLD)

Sauces or liquids filler by volumetric control, regardless of the density they may contain, either low or high.

This equipment is frequently used for the dosing of jams, yogurts, honey, creams, juices, pates, sauces and so on, even when they may contain some solid particles, as long as they are homogeneously mixed.

New equipment, with exceptional price.

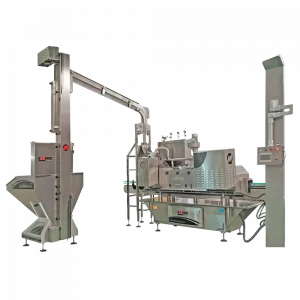

Emerito U2 Rinser System (Ref. L1620AF) (SOLD)

Equipment for sanitizing empty containers prior to filling, Model Emerito U2. The same equipment combines a pressure rinsing station and a second pressure blowing station to remove most of the residual moisture generated in the rinsing (not drying) process. This equipment has been designed for the sanitization by rinsing and blowing of glass containers or cans (rigid containers in general) up to a production speed of 150 containers per minute. One or the other treatment can be used independently or together. Impeccable condition. Delivery time from confirmation: 4 weeks.

Emerito 1.8 ACT Capping Machine (Ref. C0420FCV) (SOLD)

Emerito 1.8 glass jar capper, model Emerito 1.8.

Equipment completely reconditioned in Emerito, S.L. The maximum production rate of this equipment is 70 containers per minute. Includes steam pre-installation system.

Includes steam extraction.

Estimated delivery time from equipment confirmation is 6 weeks.

The equipment is delivered completely updated.

Emerito 1.8 ACT Capping Machine (Ref. C0420FCV) (SOLD)

Emerito 1.8 glass jar capper, model Emerito 1.8.

Equipment completely reconditioned in Emerito, S.L. The maximum production rate of this equipment is 70 containers per minute. Includes steam pre-installation system.

Includes steam extraction.

Estimated delivery time from equipment confirmation is 6 weeks.

The equipment is delivered completely updated.

Take a look at our catalogue

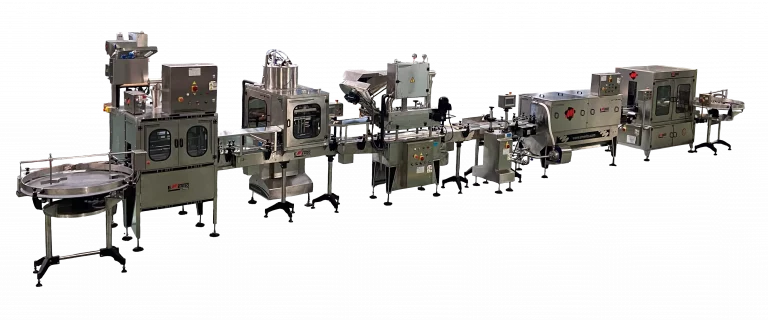

Equipment designed to depalletize rigid empty containers such as

that are already palletized, with the function to align them one by one and lead them correctly to the packaging line. It can also be used at the end of the line with full containers to align them one by one and lead them to the batch marking and labeling area.

Twist Off and PT closures. Totally adapted to your needs. Total versatility in containers, lids and products. In addition, we have the fastest container format changeover in the market.

Low Productions (Up to 40 cpm)

Emerito S1 Emerito 0.8 Emerito 4.8

Medium Productions (Up to 70 cpm)

Emerito 1.8 Emerito 1.8G

Medium-High Productions (Up to 200 cpm)

Emerito 2.8 Emerito 2.8 M2

High Productions (Up to 600 cpm)

Emerito 3.8 Emerito 5.8

Equipment that controls the quality of food packaging, checking the vacuum of each food and the placement of the lid.

Equipment designed to avoid the overfilling of solid product in the containers, prior to being closed.

Machines designed to insert and extract already closed containers into the baskets normally used in horizontal autoclaves. They can be automatic or semi-automatic, depending on the needs of each packaging line.

We have equipment to complement the processes, such as accumulation and feeding plates and tables, conveyor belts and electric steam generators.